Turbochargers have been the holy grail for power gains for many decades, stressing engine blocks to their very limits through additional horsepower and heat output. Whether your car has a turbocharger stock or has been modified with new injectors and a manifold to accommodate one, Pursuit of fast rotation of turbine blades is usually preferred.

But if a fairly sizeable chunk of additional power isn’t quite enough for your needs, twin-turbocharging could be an option, next we will have a brief introduction on how twin-turbocharging works.

Parallel twin-turbos

This is using two turbochargers of the same size to work together to force air as quickly as possible into the cylinders. The exhaust gasses recycled to the turbos are split equally between the two but usually combine again in a common inlet before entering the cylinders.

This simple turbo works much better than one big turbo doing all the work. In V-engines, each turbocharger is generally assigned its own bank of cylinders, instead of one large turbocharger having to force air through convoluted plumbing to make its way around the engine bay to the required cylinders.The lag that occurs is improved due to the habit of using slightly smaller turbos when parallel twin turbos are used instead of larger turbos with larger blades. This makes the winding process easier with incoming air.To keep these benefits while balancing the need for power, the general rule is that parallel turbos should be set at relatively low boost pressure to reduce turbo lag, but with the combination of the two turbines creating ample power.

(The picture comes from the Internet)

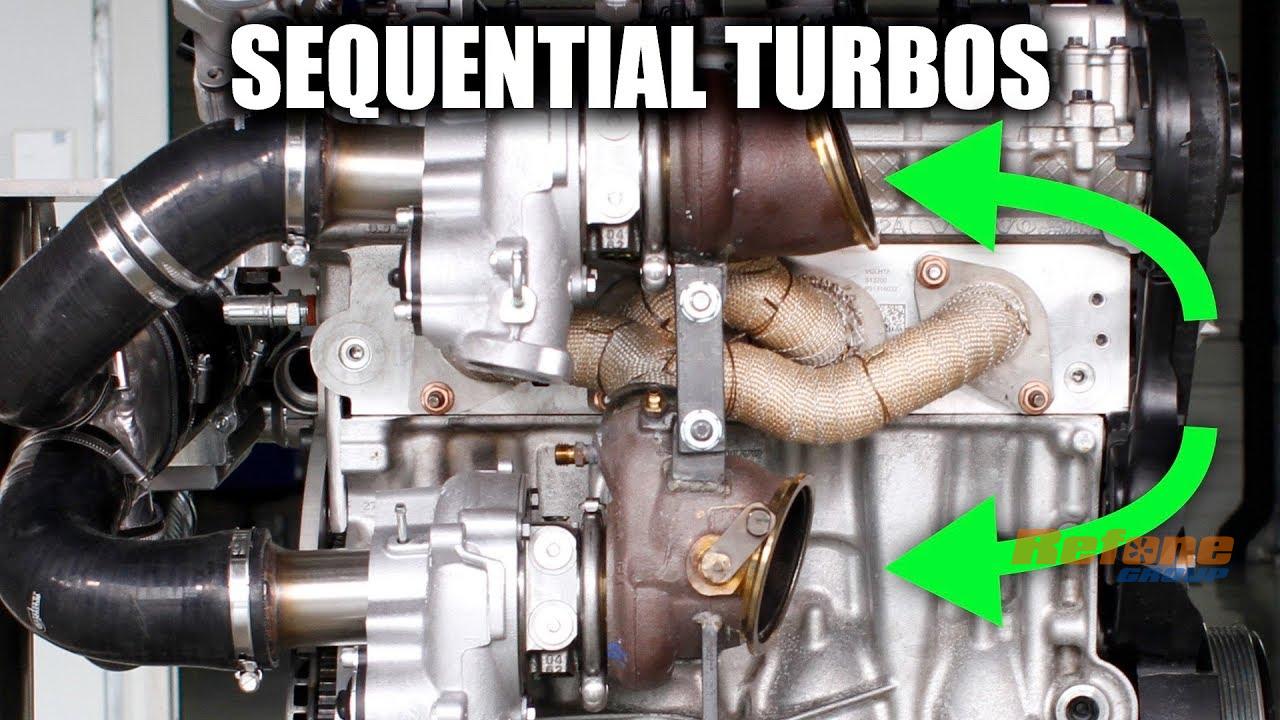

Sequential twin-turbos

This setup uses two different sizes of turbochargers; a small-vaned turbo for low exhaust gas flow at lower engine speeds and then a much larger second turbo to take over once it’s had a chance to spool up.

A compression valve sits in front of the large turbo, making sure that all of the lower energy exhaust gasses produced at the bottom end of the rev range are isolated to the smaller turbocharger to maximise power delivery at a rev range once useless to most single turbocharger setups. As the engine speed rises, the compression valve is opened slightly, allowing the larger turbine to begin to spool. The valve is then triggered to open fully at a set volume of airflow, allowing the secondary turbo to maximise its efficiency.

Sequential turbocharging therefore takes away virtually all of the downsides of single turbocharging and supersedes a parallel setup as the secondary turbo can be set to extremely high boost, relying on the primary turbo to eradicate any lag lower down. Car modifiers can also go pretty crazy with a sequential system, varying the ratio between the small and large turbocharger to create some truly scary power deliveries.

(The picture comes from the Internet)

Staged turbocharging

Using the same principles as a sequential setup, staged turbocharging uses a ‘stepped’ process to build up air compression to extremely high levels before entering the engine’s cylinders. Starting with a small turbocharger, the air is passed directly to a slightly larger turbo which compresses the air further. The final boost pressure in a staged system can be much larger than a normal twin-turbo system but is fairly catastrophic when it comes to lag. This is why it is generally used in diesel engines with high compression ratios and low rev ranges.

(The picture comes from the Internet)

Twin-scroll turbos

To save the hassle of using two turbochargers, you could opt for a twin-scroll turbo. This is effectively two turbos crammed into one casing, with the exhaust manifold strategically split between the cylinders of the engine. This is because in a normal single scroll turbocharger, the exhaust pulses converge before and inside the turbocharger, creating erratic and turbulent airflow. The twin-scroll system allows for the exhaust pulses to be kept separate and enter the turbocharger through their own inlets, minimising the clashes between the pulses

(The picture comes from the Internet)

Twin turbo is the use of one large and one small turbos or two identical turbos in parallel to reduce turbo lag when the car is accelerating rapidly, thereby bringing better ride comfort and fuel economy to the vehicle. Generally speaking, the manufacturing cost of a twin-turbo engine is higher than that of a single-turbo engine. However, the power of a twin-turbo car is generally stronger. If you like driving, seek power, and If you have enough money, then you can choose a twin-turbocharger. Details can be consulted on www.refoneturbo.com

Online Service

Online Service +86 551 65617152

+86 551 65617152 info@refoneturbo.com

info@refoneturbo.com +8618133658728

+8618133658728