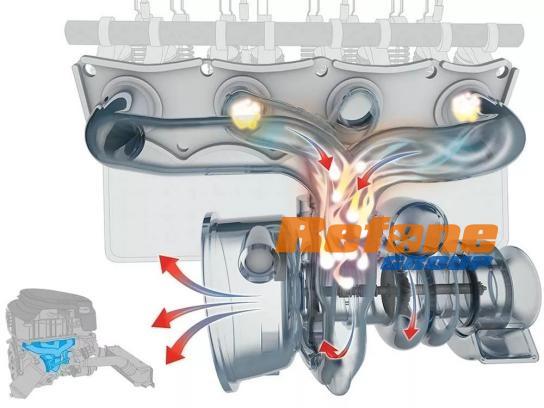

The turbocharger on the car is working to withstand the impact of high temperature and high pressure exhaust gas from the engine, and the turbo's speed is generally above tens of thousands of revolutions, up to 200,000 revolutions / min, and the temperature is also as high as 900 to 1000 ℃. In such a high working temperature and speed, how is the turbocharger lubrication and cooling it?

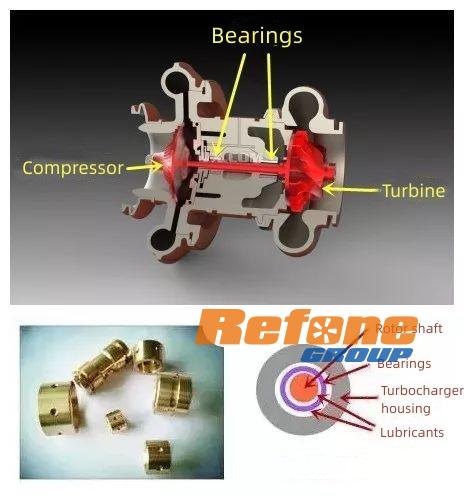

Turbocharger moving parts, but also the most core components - turbine wheel, compressor wheel and rotor shaft, and the turbocharger shell between the high-speed relative motion, this speed ordinary bearings can not withstand, so the turbocharger bearing is a special floating bearing. It is actually a copper ring set on the shaft and shell, in the ring and the shaft and between the ring and the bearing seat are clearance. When the engine is working, under the action of oil pressure, a double oil film is formed in these parts, and the rotor is actually floating on the oil film rotating at high speed. Because of the extremely high speed and temperature, this part also has extremely high requirements for lubrication and cooling.

If the turbocharger does not get good lubrication and cooling, will cause abnormal bearing wear, greatly shorten the service life of the bearing, the gap between the rotor and the shell increases, part of the oil from this part into the intake or exhaust pipe, resulting in serious oil burning failure; in addition, poor heat dissipation will lead to oil coking or carbon, which further damage the turbocharger seal and lubrication, intensifying the wear and tear, eventually leading to turbocharger Oil leaks or strange noise, and in serious cases, even jamming.

Turbocharger bearing damage type

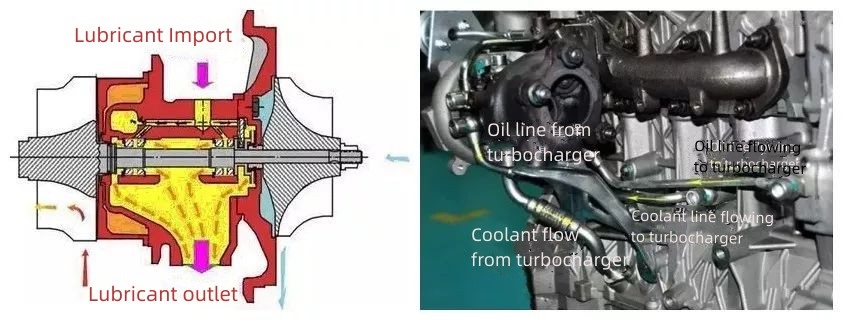

In order to cool and lubricate the turbocharger, an oil pipe is specially divided from the main oil channel of the engine lubrication system, so that the oil enters from the oil inlet above the turbocharger intermediate and flows out from the oil port below the intermediate to lubricate and cool the turbocharger rotor and bearings. In order to ensure good lubrication and cooling effect, the flow rate of this part of the oil is very fast and the flow rate is relatively large. Nowadays, in order to better cool the turbocharger, some models have also added a water-cooling device and driven by an electronic water pump, which can still work for a few minutes after the engine is turned off and continue to dissipate heat to the turbocharger to prevent the turbocharger from getting too hot.

Due to this special cooling and lubrication of the turbocharger, so there are certain requirements on the use of the turbocharger, such as cold start immediately after the high-speed operation, do not idle for a long time, do not immediately turn off the engine after a long period of heavy load running, do not blow the throttle before turning off the engine, and so on. In addition, turbochargers must use high-quality fully synthetic oil to prevent poor lubrication or oil coking at high temperatures, when replacing the turbocharger should also inject a certain amount of oil into the turbocharger to prevent the engine from starting instantly turbocharger without lubrication and burn.

Online Service

Online Service +86 551 65617152

+86 551 65617152 info@refoneturbo.com

info@refoneturbo.com +8618133658728

+8618133658728