The measurement tools we generally choose are Coordinate Measuring Machine, Imaging instrument and Vernier calipers. Coordinate Measuring Machine, Imaging instrument are used for accurate measurement, but vernier calipers are generally used the most. It is easy to calibrate, easy to operate, and has a variety of measurement functions and data integration.

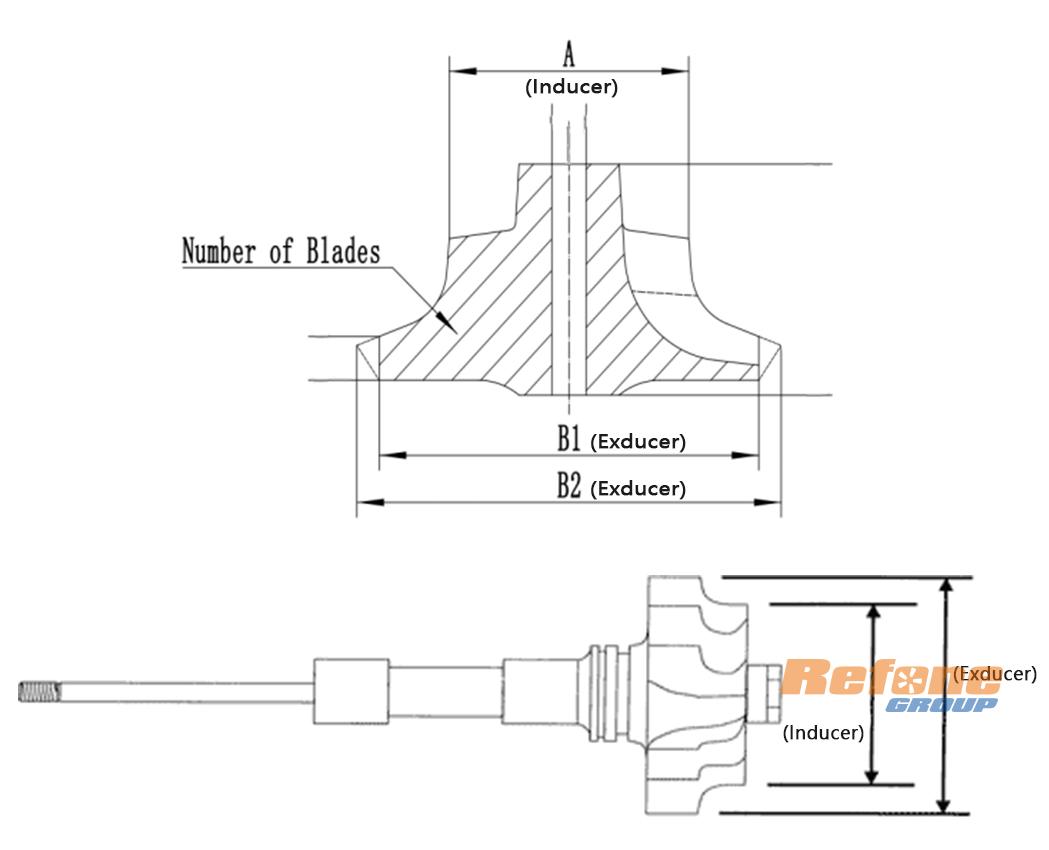

Turbine wheels generally have 8, 9, 10, 11, 12 blades. The calculation of the compressor wheels blades is somewhat different from that of a turbine wheels. The compressor wheels is divided into long wheels and long & short wheels .

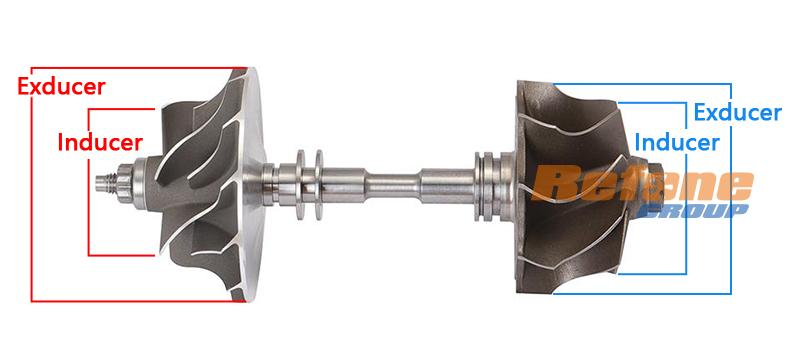

The measurement method of Turbine wheels and compressor wheels is the same, the caliper is clamped on the wheel diameter and the diameter data is obtained.

Please contact Refone as soon as possible, our professional technicians will confirm the OE size for you and help you make reasonable performance.

Online Service

Online Service +86 551 65617152

+86 551 65617152 info@refoneturbo.com

info@refoneturbo.com +8618133658728

+8618133658728